Camera Integration

Rayforge supports USB camera integration for precise material alignment and positioning. The camera overlay feature allows you to see exactly where your laser will cut or engrave on the material, eliminating guesswork and reducing material waste.

Overview

The camera integration provides:

- Live video overlay on the canvas showing your material in real-time

- Image alignment to calibrate camera position relative to the laser

- Visual positioning to accurately place jobs on irregular or pre-marked materials

- Material preview before running jobs

- Multiple camera support for different machine setups

- Aligning cuts on pre-printed materials

- Working with irregularly shaped materials

- Precise placement of engravings on existing objects

- Reducing test cuts and material waste

Camera Setup

Hardware Requirements

Compatible cameras:

- USB webcams (most common)

- Laptop built-in cameras (if running Rayforge on laptop near machine)

- Any camera supported by Video4Linux2 (V4L2) on Linux or DirectShow on Windows

Recommended setup:

- Camera mounted above the work area with clear view of material

- Consistent lighting conditions

- Camera positioned to capture the laser work area

- Secure mounting to prevent camera movement

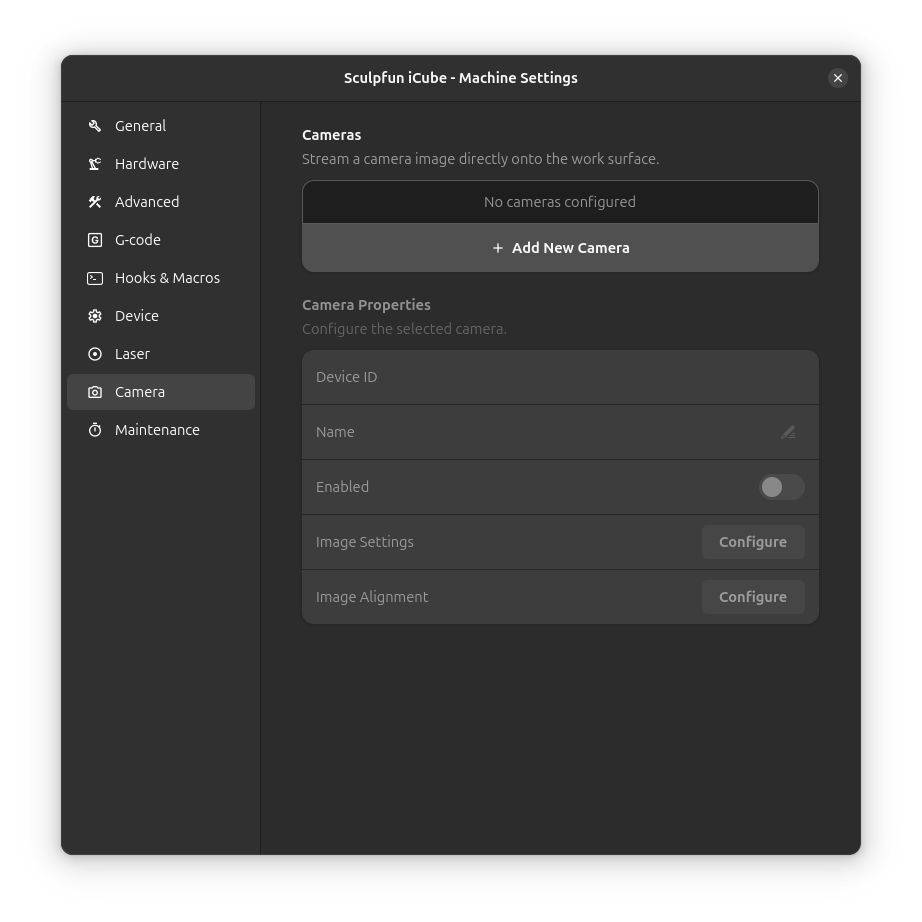

Adding a Camera

-

Connect your camera to your computer via USB

-

Open Camera Settings:

- Navigate to Settings Preferences Camera

- Or use the camera toolbar button

-

Add a new camera:

- Click the "+" button to add a camera

- Enter a descriptive name (e.g., "Top Camera", "Work Area Cam")

- Select the device from the dropdown

- On Linux:

/dev/video0,/dev/video1, etc. - On Windows: Camera 0, Camera 1, etc.

- On Linux:

-

Enable the camera:

- Toggle the camera enable switch

- The live feed should appear on your canvas

-

Adjust camera settings:

- Brightness: Adjust if material is too dark/bright

- Contrast: Enhance edge visibility

- Transparency: Control overlay opacity (20-50% recommended)

- White Balance: Auto or manual Kelvin temperature

Camera Alignment

Camera alignment calibrates the relationship between camera pixels and real-world coordinates, enabling accurate positioning.

Why Alignment is Necessary

The camera sees the work area from above, but the image may be:

- Rotated relative to the machine axes

- Scaled differently in X and Y directions

- Distorted by lens perspective

Alignment creates a transformation matrix that maps camera pixels to machine coordinates.

Alignment Procedure

-

Open the Alignment Dialog:

- Click the camera alignment button in the toolbar

- Or go to Camera Align Camera

-

Place alignment markers:

- You need at least 3 reference points (4 recommended for better accuracy)

- Alignment points should be spread across the work area

- Use known positions like:

- Machine home position

- Ruler markings

- Pre-cut alignment holes

- Calibration grid

-

Mark image points:

- Click on the camera image to place a point at a known location

- The bubble widget appears showing point coordinates

- Repeat for each reference point

-

Enter world coordinates:

- For each image point, enter the real-world X/Y coordinates in mm

- These are the actual machine coordinates where each point is located

- Measure accurately with a ruler or use known machine positions

-

Apply alignment:

- Click "Apply" to calculate the transformation

- The camera overlay will now be properly aligned

-

Verify alignment:

- Move the laser head to a known position

- Check that the laser dot aligns with the expected position in the camera view

- Fine-tune by re-aligning if needed

Alignment Tips

- Use points at the corners of your work area for maximum coverage

- Avoid clustering points in one area

- Measure world coordinates carefully - accuracy here determines overall alignment quality

- Re-align if you move the camera or change the focus distance

- Save your alignment - it persists across sessions

Example alignment workflow:

- Move laser to home position (0, 0) and mark in camera

- Move laser to (100, 0) and mark in camera

- Move laser to (100, 100) and mark in camera

- Move laser to (0, 100) and mark in camera

- Enter exact coordinates for each point

- Apply and verify

Using the Camera Overlay

Once aligned, the camera overlay helps position jobs accurately.

Enabling/Disabling the Overlay

- Toggle camera: Click the camera icon in the toolbar

- Adjust transparency: Use the slider in camera settings (20-50% works well)

- Refresh image: Camera updates continuously while enabled

Positioning Jobs with the Camera

Workflow for precise placement:

-

Enable the camera overlay to see your material

-

Import your design (SVG, DXF, etc.)

-

Position the design on the canvas:

- Drag the design to align with features visible in the camera

- Use zoom to see fine details

- Rotate/scale as needed

-

Preview the alignment:

- Use the Simulation Mode to visualize

- Check that cuts/engravings will be where you expect

-

Frame the job to verify positioning before running

-

Run the job with confidence

Example: Engraving on a Pre-Printed Card

- Place the printed card on the laser bed

- Enable camera overlay

- Import your engraving design

- Drag and position the design to align with printed features

- Fine-tune position using arrow keys

- Frame to verify

- Run the job

Camera Settings Reference

Device Settings

| Setting | Description | Values |

|---|---|---|

| Name | Descriptive name for the camera | Any text |

| Device ID | System device identifier | /dev/video0 (Linux), 0 (Windows) |

| Enabled | Camera active state | On/Off |

Image Adjustment

| Setting | Description | Range |

|---|---|---|

| Brightness | Overall image brightness | -100 to +100 |

| Contrast | Edge definition and contrast | 0 to 100 |

| Transparency | Overlay opacity on canvas | 0% (opaque) to 100% (transparent) |

| White Balance | Color temperature correction | Auto or 2000-10000K |

Alignment Data

| Property | Description |

|---|---|

| Image Points | Pixel coordinates in camera image |

| World Points | Real-world machine coordinates (mm) |

| Transformation Matrix | Calculated mapping (internal) |

Advanced Features

Camera Calibration (Lens Distortion Correction)

For precise work, you can calibrate the camera to correct barrel/pincushion distortion:

- Print a checkerboard pattern (e.g., 86 grid with 25mm squares)

- Capture 10+ images of the pattern from different angles/positions

- Use OpenCV calibration tools to calculate camera matrix and distortion coefficients

- Apply calibration in Rayforge (advanced settings)

Lens distortion correction is only necessary for:

- Wide-angle lenses with noticeable barrel distortion

- Precision work requiring <1mm accuracy

- Large work areas where distortion accumulates

Most standard webcams work fine without calibration for typical laser work.

Multiple Cameras

Rayforge supports multiple cameras for different views or machines:

- Add multiple cameras in preferences

- Each camera can have independent alignment

- Switch between cameras using the camera selector

- Use cases:

- Top view + side view for 3D objects

- Different cameras for different machines

- Wide angle + detail camera

Troubleshooting

Camera Not Detected

Problem: Camera doesn't appear in device list.

Solutions:

Linux: Check if the camera is recognized by the system:

# List video devices

ls -l /dev/video*

# Check camera with v4l2

v4l2-ctl --list-devices

# Test with another application

cheese # or VLC, etc.

For Snap users:

# Grant camera access

sudo snap connect rayforge:camera

Windows:

- Check Device Manager for camera under "Cameras" or "Imaging devices"

- Ensure no other application is using the camera (close Zoom, Skype, etc.)

- Try a different USB port

- Update camera drivers

Camera Shows Black Screen

Problem: Camera detected but shows no image.

Possible causes:

- Camera in use by another application - Close other video apps

- Incorrect device selected - Try different device IDs

- Camera permissions - On Linux Snap, ensure camera interface connected

- Hardware issue - Test camera with another application

Solutions:

# Linux: Release camera device

sudo killall cheese # or other camera apps

# Check which process is using the camera

sudo lsof /dev/video0

Alignment Not Accurate

Problem: Camera overlay doesn't match real laser position.

Diagnosis:

- Insufficient alignment points - Use at least 4 points

- Measurement errors - Double-check world coordinates

- Camera moved - Re-align if camera position changed

- Non-linear distortion - May need lens calibration

Improve accuracy:

- Use more alignment points (6-8 for very large areas)

- Spread points across entire work area

- Measure world coordinates very carefully

- Use machine movement commands to precisely position laser at known coordinates

- Re-align after any camera adjustments

Poor Image Quality

Problem: Camera image is blurry, dark, or washed out.

Solutions:

- Adjust brightness/contrast in camera settings

- Improve lighting - Add consistent work area lighting

- Clean camera lens - Dust and debris reduce clarity

- Check focus - Auto-focus may not work well; use manual if possible

- Reduce transparency temporarily to see camera image more clearly

- Try different white balance settings

Camera Lag or Stuttering

Problem: Live camera feed is choppy or delayed.

Solutions:

- Lower camera resolution in device settings (if accessible)

- Close other applications using CPU/GPU

- Update graphics drivers

- On Linux, ensure using V4L2 backend (automatic in Rayforge)

- Disable camera when not needed to save resources

Related Pages

- Simulation Mode - Preview execution with camera overlay

- 3D Preview - Visualize jobs in 3D

- Framing Jobs - Verify job position

- General Settings - Machine configuration