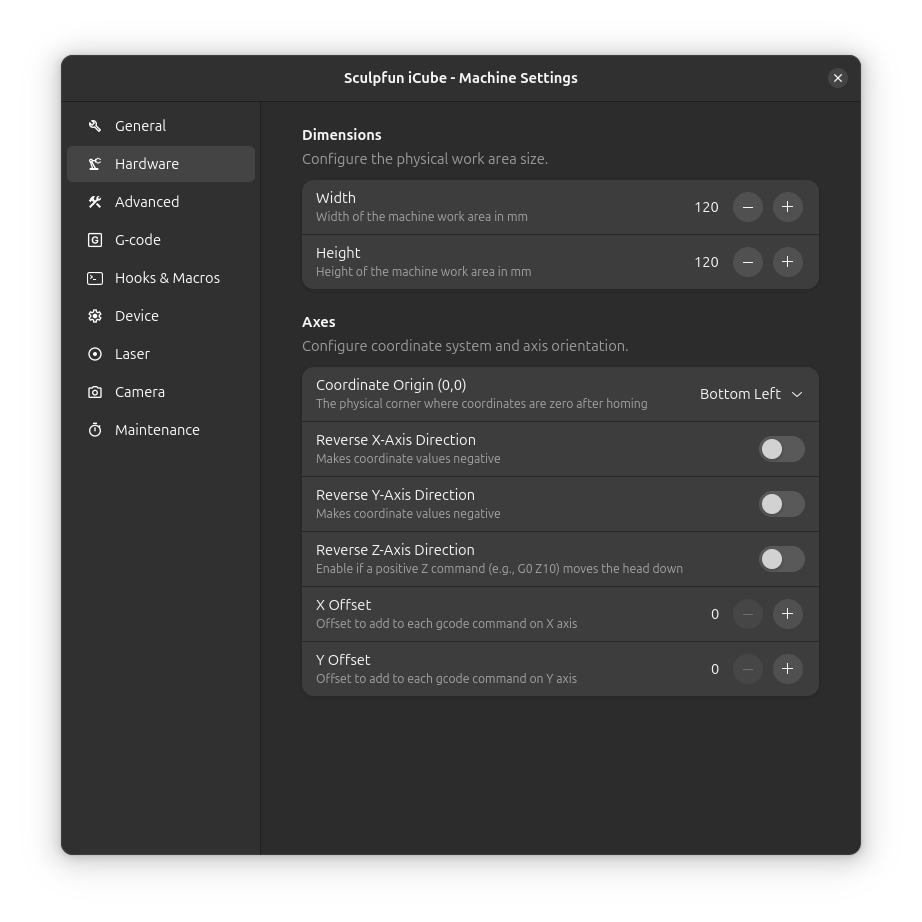

Hardware Settings

The Hardware page in Machine Settings configures the physical dimensions and axis orientation of your machine.

Work Area Dimensions

Define the size of your machine's working area in millimeters.

Width

The horizontal (X-axis) dimension of your working area.

- Measure the actual cutting area, not the machine exterior

- Account for any obstructions or limits

- Example: 400mm for a typical K40 laser

Height

The vertical (Y-axis) dimension of your working area.

- Measure the actual cutting area

- Consider the laser head travel limits

- Example: 300mm for a typical K40 laser

Measuring Work Area

To find your true work area:

- Home the machine

- Manually jog to the maximum X and Y positions

- Measure from the homing corner to the maximum reach

Coordinate Origin

Select where your machine's coordinate origin (0,0) is located. This determines how coordinates are interpreted.

Available Options

- Bottom Left: Most common for GRBL devices. X increases to the right, Y increases upward.

- Top Left: Common for some CNC-style machines. X increases to the right, Y increases downward.

- Top Right: X increases to the left, Y increases downward.

- Bottom Right: X increases to the left, Y increases upward.

Finding Your Origin

- Home your machine using the Home button

- Observe where the laser head moves to

- That position is your (0,0) origin

info

The coordinate origin setting affects how G-code is generated. Make sure it matches your firmware's homing configuration.

See Also

- General Settings - Machine name and speed settings

- Device Settings - GRBL homing and axis settings