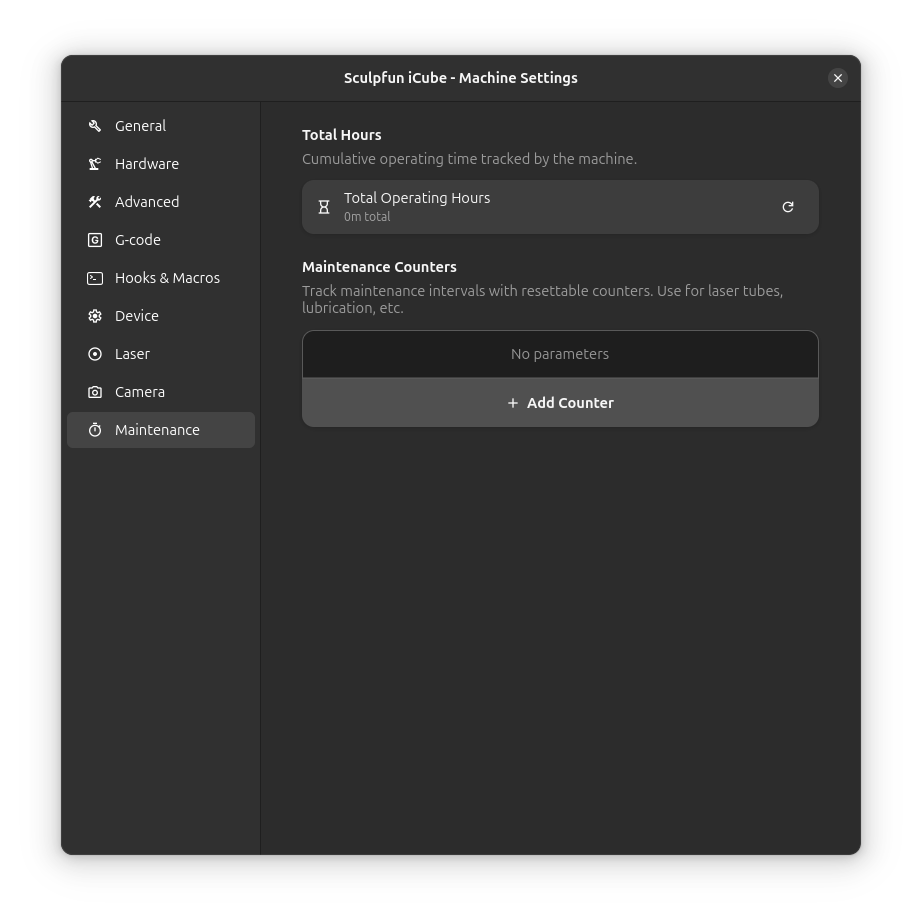

Maintenance

The Maintenance page in Machine Settings helps you track machine usage and schedule maintenance tasks.

Hour Counters

Rayforge tracks how long your machine has been in use. These counters help you schedule preventive maintenance.

Laser Hours

Tracks the total time the laser has been firing. Use this to:

- Schedule laser tube replacement (CO2 tubes typically last 1000-3000 hours)

- Monitor laser diode degradation

- Track warranty periods

Job Hours

Tracks the total time spent running jobs, including travel moves. Use this to:

- Schedule belt tensioning

- Plan bearing lubrication

- Track overall machine usage

Movement Hours

Tracks the time spent moving (not cutting). Use this to:

- Schedule stepper motor maintenance

- Plan rail cleaning and lubrication

Resetting Counters

After performing maintenance, you can reset the relevant counter:

- Click the reset button next to the counter

- Confirm the reset in the dialog

- The counter returns to zero

Maintenance Schedule

Common maintenance intervals:

- Daily: Clean lens, check mirror alignment

- Weekly: Clean rails, check belt tension

- Monthly: Lubricate bearings, check electrical connections

- Yearly: Full inspection, replace worn parts

See Also

- Laser Settings - Laser head configuration

- Hardware Settings - Machine dimensions