Macros & Hooks

Rayforge provides two powerful automation features for customizing your workflow: Macros and Hooks. Both allow you to inject custom G-code into your jobs, but they serve different purposes.

Overview

| Feature | Purpose | Trigger | Use Case |

|---|---|---|---|

| Macros | Reusable G-code snippets | Manual execution | Quick commands, test patterns, custom routines |

| Hooks | Automatic G-code injection | Job lifecycle events | Startup sequences, layer changes, cleanup |

Macros

Macros are named, reusable G-code scripts that you can execute manually at any time.

What Are Macros For?

Common macro use cases:

- Homing the machine - Send

$Hquickly - Setting work offsets - Store and recall G54/G55 positions

- Air assist control - Toggle air assist on/off

- Focus testing - Run a quick focus test pattern

- Custom tool changes - For multi-laser setups

- Emergency routines - Quick shutdown or alarm clear

- Material probing - Auto-focus or height measurement

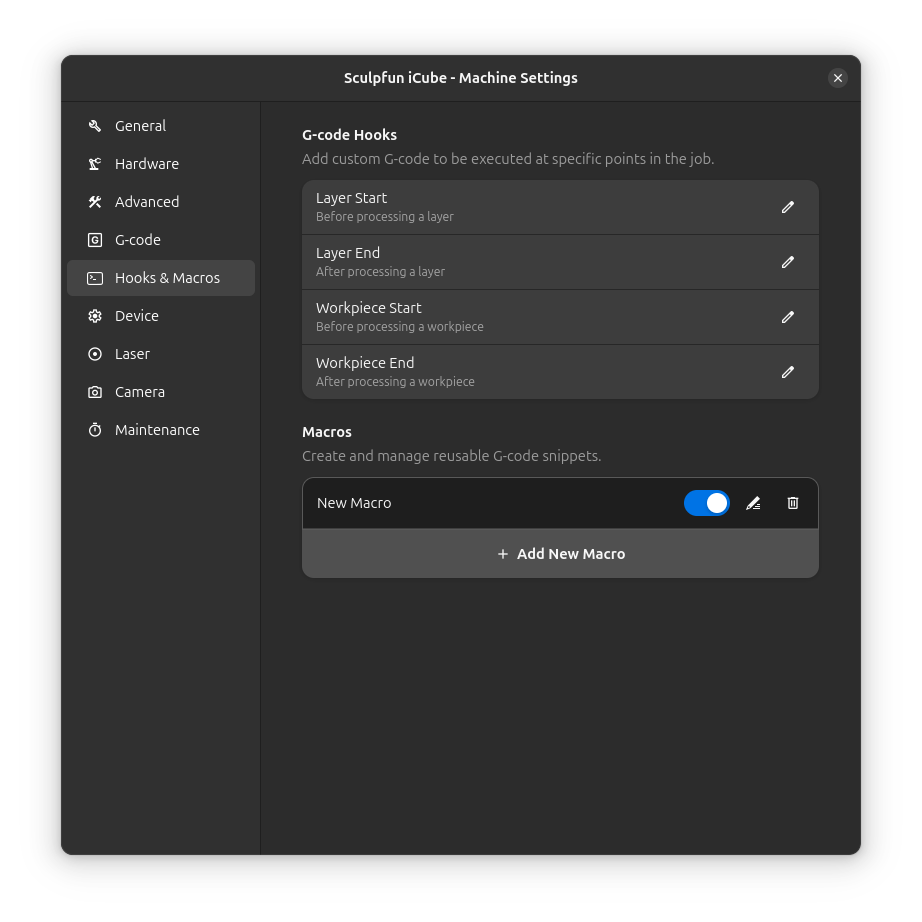

Creating a Macro

-

Open Machine Settings:

- Navigate to Settings Machine Macros

-

Add a new macro:

- Click the "+" button

- Enter a descriptive name (e.g., "Home Machine", "Enable Air Assist")

-

Write your G-code:

- Each line is a separate G-code command

- Comments start with

;or( - Variables can be used (see Variable Substitution below)

-

Save the macro

-

Execute the macro:

- From the macros list, click the macro

- Or assign a keyboard shortcut (if supported)

Example Macros

Simple: Home the Machine

Name: Home Machine Code:

$H

; Waits for homing to complete

Use: Quickly home the machine before starting work.

Medium: Set Work Offset

Name: Set G54 to Current Position Code:

G10 L20 P1 X0 Y0

; Sets G54 work coordinate system origin to current position

Use: Mark the current laser position as the job origin.

Advanced: Focus Test Grid

Name: 9-Point Focus Test Code:

; 9-point grid for finding optimal focus

G21 ; Millimeters

G90 ; Absolute positioning

G0 X10 Y10

M3 S1000

G4 P0.1

M5

G0 X20 Y10

M3 S1000

G4 P0.1

M5

; ... (repeat for remaining points)

Use: Quickly test focus at different positions on the bed.

Macro Examples

Hooks are automatic G-code injections triggered by specific events during job execution.

Hook Triggers

Rayforge supports these hook triggers:

| Trigger | When It Runs | Common Uses |

|---|---|---|

| Job Start | Very beginning of the job | Homing, work offset, air assist on, preheat |

| Job End | Very end of the job | Return home, air assist off, beep, cooldown |

| Layer Start | Before processing each layer | Tool change, power adjust, comments |

| Layer End | After processing each layer | Progress notification, pause |

| Workpiece Start | Before processing each workpiece | Part numbering, alignment marks |

| Workpiece End | After processing each workpiece | Cooldown, inspection pause |

Creating a Hook

-

Open Machine Settings:

- Navigate to Settings Machine Hooks

-

Select a trigger:

- Choose the event when this hook should run

-

Write your G-code:

- Hook code is injected at the trigger point

- Use variables for dynamic values (see below)

-

Enable/disable:

- Toggle hooks on/off without deleting them

Example Hooks

Job Start: Initialize Machine

Trigger: Job Start Code:

G21 ; Millimeters

G90 ; Absolute positioning

$H ; Home the machine

G0 X0 Y0 ; Move to origin

M3 S0 ; Laser on but power 0 (some controllers need this)

M8 ; Air assist ON

Purpose: Ensures machine is in a known state before every job.

Job End: Return Home and Beep

Trigger: Job End Code:

M5 ; Laser OFF

M9 ; Air assist OFF

G0 X0 Y0 ; Return to origin

M300 S800 P200 ; Beep (if supported)

Purpose: Safely ends the job and signals completion.

Layer Start: Add Comment

Trigger: Layer Start Code:

; Starting layer: {layer_name}

; Layer index: {layer_index}

Purpose: Makes G-code more readable for debugging.

Workpiece Start: Part Numbering

Trigger: Workpiece Start Code:

; Part: {workpiece_name}

; Part {workpiece_index} of {total_workpieces}

Purpose: Track progress in multi-part jobs.

Hook Execution Order

For a job with 2 layers, each with 2 workpieces:

[Job Start Hook]

[Layer Start Hook] (Layer 1)

[Workpiece Start Hook] (Workpiece 1)

... workpiece 1 G-code ...

[Workpiece End Hook] (Workpiece 1)

[Workpiece Start Hook] (Workpiece 2)

... workpiece 2 G-code ...

[Workpiece End Hook] (Workpiece 2)

[Layer End Hook] (Layer 1)

[Layer Start Hook] (Layer 2)

[Workpiece Start Hook] (Workpiece 3)

... workpiece 3 G-code ...

[Workpiece End Hook] (Workpiece 3)

[Workpiece Start Hook] (Workpiece 4)

... workpiece 4 G-code ...

[Workpiece End Hook] (Workpiece 4)

[Layer End Hook] (Layer 2)

[Job End Hook]

Variable Substitution

Both macros and hooks support variable substitution to inject dynamic values.

Available Variables

Variables use {variable_name} syntax and are replaced during G-code generation.

Job-level variables:

| Variable | Description | Example Value |

|---|---|---|

{job_name} | Name of the current job/document | "test-job" |

{date} | Current date | "2025-10-03" |

{time} | Current time | "14:30:25" |

Layer-level variables:

| Variable | Description | Example Value |

|---|---|---|

{layer_name} | Name of the current layer | "Cut Layer" |

{layer_index} | Zero-based index of current layer | 0, 1, 2... |

{total_layers} | Total number of layers in job | 3 |

Workpiece-level variables:

| Variable | Description | Example Value |

|---|---|---|

{workpiece_name} | Name of the workpiece | "Circle 1" |

{workpiece_index} | Zero-based index of current workpiece | 0, 1, 2... |

{total_workpieces} | Total number of workpieces | 5 |

Machine variables:

| Variable | Description | Example Value |

|---|---|---|

{machine_name} | Name of the machine profile | "My K40" |

{max_speed} | Maximum cutting speed (mm/min) | 1000 |

{work_width} | Work area width (mm) | 300 |

{work_height} | Work area height (mm) | 200 |

Example: Progress Notification

Hook: Layer Start Code:

; ========================================

; Layer {layer_index} of {total_layers}: {layer_name}

; Job: {job_name}

; Time: {time}

; ========================================

Result in G-code:

; ========================================

; Layer 0 of 3: Cut Layer

; Job: test-project

; Time: 14:30:25

; ========================================

Advanced Use Cases

Multi-Tool Setup

For machines with multiple lasers or tools:

Hook: Workpiece Start Code:

; Select tool for workpiece {workpiece_name}

T{tool_number} ; Tool change command (if supported)

G4 P1 ; Wait for tool change

Conditional Pauses

Add optional pauses for inspection:

Hook: Layer End Code:

; M0 ; Uncomment to pause after each layer for inspection

Air Assist Per Layer

Control air assist on a per-layer basis:

Hook: Layer Start (for cutting layers) Code:

M8 ; Air assist ON

Hook: Layer Start (for engraving layers) Code:

M9 ; Air assist OFF (prevents dust scattering for engraving)

Rayforge doesn't currently support per-layer hook customization. To achieve this, use conditional G-code or separate machine profiles.

Safety Considerations

Always test macros and hooks in simulation mode or with the laser disabled before running on real jobs. Incorrectly configured G-code can:

- Crash the machine into limits

- Fire the laser unexpectedly

- Damage materials or equipment

Safety checklist:

- Macros include feedrate limits (

Fparameter) - Macros check position bounds

- Job Start hooks include

M5or laser off command - Job End hooks turn off laser (

M5) and air assist (M9) - No destructive commands without confirmation

- Tested in simulation or with laser disabled

Related Pages

- Device Settings - GRBL command reference

- G-code Dialects - G-code compatibility

- General Settings - Machine configuration

- Multi-Layer Workflow - Using hooks with layers