Shrink Wrap

Shrink Wrap creates an efficient cutting path around multiple objects by generating a boundary that "shrinks" around them. It's useful for cutting multiple parts from a sheet with minimal waste.

Overview

Shrink Wrap operations:

- Create boundary paths around groups of objects

- Minimize material waste

- Reduce cutting time by combining paths

- Support offset distances for clearance

- Work with any combination of vector shapes

When to Use Shrink Wrap

Use shrink wrap for:

- Cutting multiple small parts from a sheet

- Minimizing material waste

- Creating efficient nesting boundaries

- Separating groups of parts

- Reducing total cutting time

Don't use shrink wrap for:

- Single objects (use Contour instead)

- Parts that need individual boundaries

- Precise rectangular cuts

How Shrink Wrap Works

Shrink wrap creates a boundary using a computational geometry algorithm:

- Start with a convex hull around all objects

- Shrink the boundary inward toward the objects

- Wrap tightly around the object group

- Offset outward by the specified distance

The result is an efficient cutting path that follows the overall shape of your parts while maintaining clearance.

Creating a Shrink Wrap Operation

Step 1: Arrange Objects

- Place all parts you want to wrap on the canvas

- Position them with desired spacing

- Multiple separate groups can be shrink-wrapped together

Step 2: Select Objects

- Select all objects to include in the shrink wrap

- Can be different shapes, sizes, and types

- All selected objects will be wrapped together

Step 3: Add Shrink Wrap Operation

- Menu: Operations Add Shrink Wrap

- Right-click: Context menu Add Operation Shrink Wrap

Step 4: Configure Settings

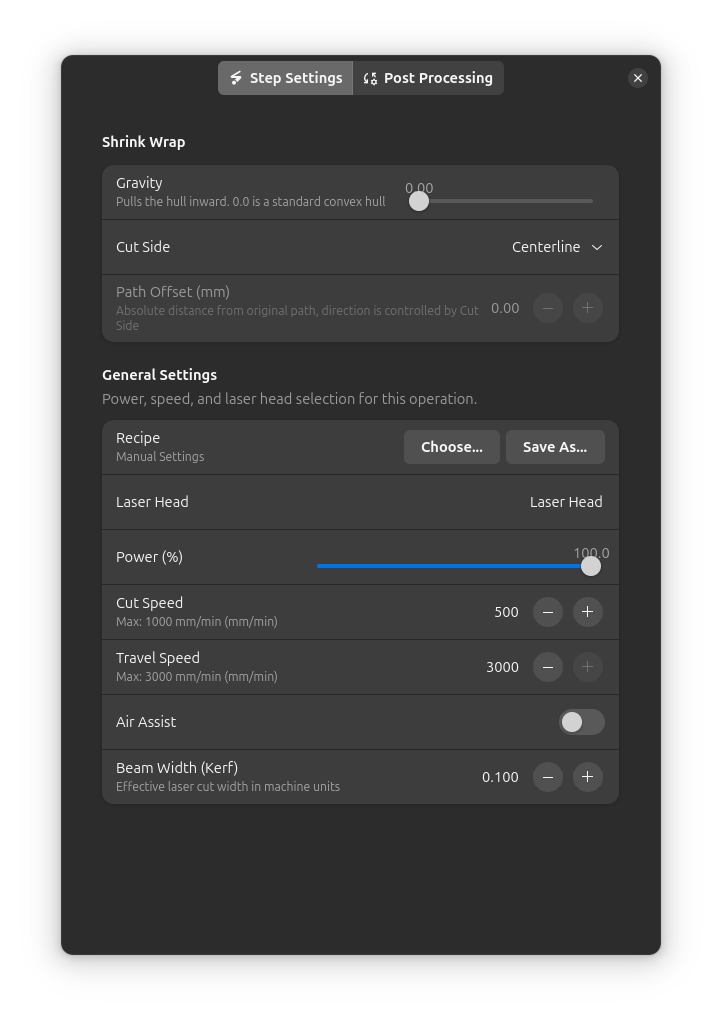

Key Settings

Power & Speed

Like other cutting operations:

Power (%):

- Laser intensity for cutting

- Same as you'd use for Contour cutting

Speed (mm/min):

- How fast the laser moves

- Match your material's cutting speed

Passes:

- Number of times to cut the boundary

- Usually 1-2 passes

- Same as contour cutting for your material

Offset Distance

Offset (mm):

- How much clearance around the parts

- Distance from objects to the shrink-wrap boundary

- Larger offset = more material left around parts

Typical values:

- 2-3mm: Tight wrap, minimal waste

- 5mm: Comfortable clearance

- 10mm+: Extra material for handling

Why offset matters:

- Too small: Risk cutting into parts

- Too large: Wastes material

- Consider: Kerf width, cutting accuracy

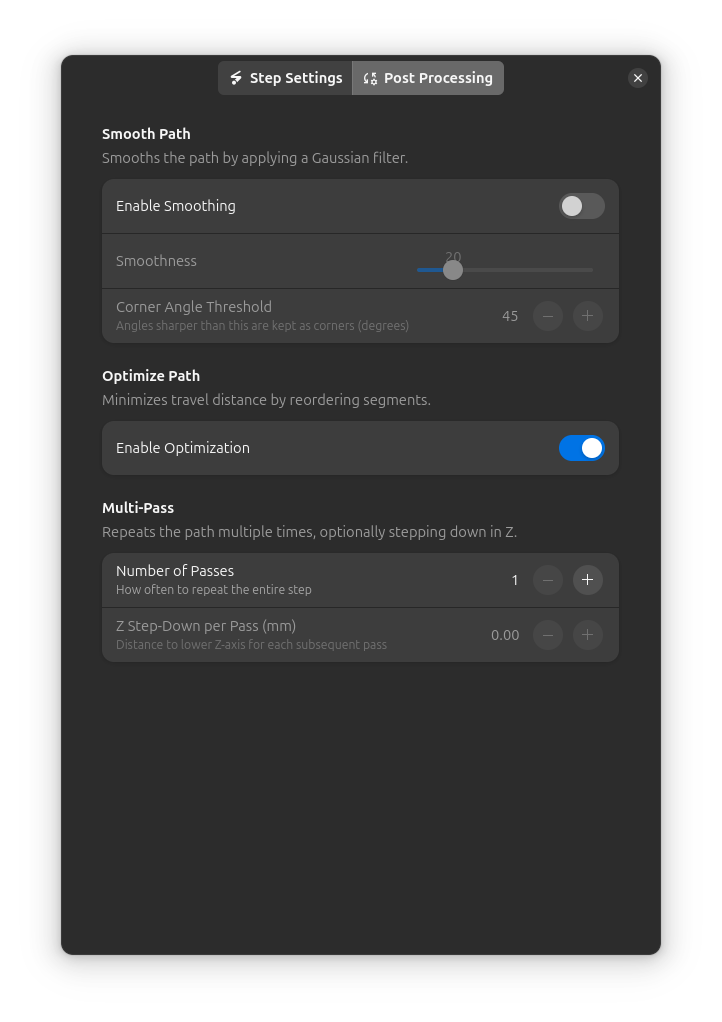

Smoothness

Controls how closely the boundary follows object shapes:

High smoothness:

- Follows objects more closely

- More complex path

- Longer cutting time

- Less material waste

Low smoothness:

- Simpler, more rounded path

- Shorter cutting time

- Slightly more material waste

Recommended: Medium smoothness for most cases

Use Cases

Batch Part Production

Scenario: Cutting 20 small parts from a large sheet

Without shrink wrap:

- Cut full sheet boundary

- Waste all material around parts

- Long cutting time

With shrink wrap:

- Cut tight boundary around part group

- Save material for other projects

- Faster cutting (shorter perimeter)

Nesting Optimization

Workflow:

- Nest parts efficiently on sheet

- Group parts into sections

- Shrink wrap each section

- Cut sections separately

Benefits:

- Can remove finished sections while continuing

- Easier handling of cut parts

- Reduced risk of part movement

Material Conservation

Example: Small parts on expensive material

Process:

- Arrange parts tightly

- Shrink wrap with 3mm offset

- Cut free from sheet

- Save remaining material

Result: Maximum material efficiency

Combining with Other Operations

Shrink Wrap + Contour

Common workflow:

- Contour operations on individual parts (cut details)

- Shrink wrap around the group (cut free from sheet)

Execution order:

- First: Cut details in parts (while secured)

- Last: Shrink wrap cuts group free

See Multi-Layer Workflow for details.

Shrink Wrap + Raster

Example: Engraved and cut parts

- Raster engrave logos on parts

- Contour cut part outlines

- Shrink wrap around entire group

Benefits:

- All engraving happens while material is secured

- Final shrink wrap cuts entire batch free

Tips & Best Practices

Part Spacing

Optimal spacing:

- 5-10mm between parts

- Enough for shrink wrap to distinguish separate objects

- Not so much that you waste material

Too close:

- Parts may be wrapped together

- Shrink wrap may bridge gaps

- Difficult to separate after cutting

Too far:

- Wastes material

- Longer cutting time

- Inefficient use of sheet

Material Considerations

Best for:

- Production runs (many identical parts)

- Small parts from large sheets

- Expensive materials (minimize waste)

- Batch cutting jobs

Not ideal for:

- Single large parts

- Parts filling entire sheet

- When you need full sheet cut

Safety

Always:

- Check that boundary doesn't overlap parts

- Verify offset is sufficient

- Preview in Simulation Mode

- Test on scrap first

Watch for:

- Shrink wrap cutting into parts (increase offset)

- Parts moving before shrink wrap completes

- Material warping pulling parts out of position

Advanced Techniques

Multiple Shrink Wraps

Create separate boundaries for different groups:

Process:

- Arrange parts into logical groups

- Shrink wrap Group 1 (top parts)

- Shrink wrap Group 2 (bottom parts)

- Cut groups separately

Benefits:

- Remove finished groups during job

- Better organization

- Easier part retrieval

Nested Shrink Wraps

Shrink wrap within a larger boundary:

Example:

- Inner shrink wrap: Small detailed parts

- Outer shrink wrap: Includes larger parts

- Contour: Full sheet boundary

Use for: Complex multi-part layouts

Clearance Testing

Before production run:

- Create shrink wrap

- Preview with Simulation Mode

- Verify clearance is adequate

- Check no parts are intersected

- Run test on scrap material

Troubleshooting

Shrink wrap cuts into parts

- Increase: Offset distance

- Check: Parts aren't too close together

- Verify: Shrink wrap path in preview

- Account for: Kerf width (laser beam width)

Boundary doesn't follow shapes

- Increase: Smoothness setting

- Check: Parts are properly selected

- Try: Smaller offset (might be wrapping too far out)

Parts are wrapped together

- Increase: Spacing between parts

- Add: Manual contours around individual parts

- Split: Into multiple shrink wrap operations

Cutting takes too long

- Decrease: Smoothness (simpler path)

- Increase: Offset (straighter boundaries)

- Consider: Multiple smaller shrink wraps

Parts move during cutting

- Add: Small tabs to hold parts (see Holding Tabs)

- Use: Cutting order: inside to outside

- Ensure: Material is flat and secured

- Check: Sheet isn't warped

Technical Details

Algorithm

Shrink wrap uses computational geometry:

- Convex hull - Find outer boundary

- Alpha shape - Shrink toward objects

- Offset - Expand by offset distance

- Simplify - Based on smoothness setting

Path Optimization

The boundary path is optimized for:

- Minimum total length

- Smooth curves (based on smoothness)

- Efficient start/end points

Coordinate System

- Units: Millimeters (mm)

- Precision: 0.01mm typical

- Coordinates: Same as workspace

Related Topics

- Contour Cutting - Cutting individual object outlines

- Multi-Layer Workflow - Combining operations effectively

- Holding Tabs - Keeping parts secure during cutting

- Simulation Mode - Previewing cutting paths

- Material Test Grid - Finding optimal cutting settings