Engrave

Engrave operations fill areas with raster scanning lines, supporting multiple modes for different engraving effects. From smooth grayscale photos to 3D relief effects, choose the mode that best suits your design and material.

Overview

Engrave operations:

- Fill closed shapes with scanning lines

- Support multiple engraving modes for different effects

- Work with both vector shapes and bitmap images

- Use bidirectional scanning for speed

- Create permanent marks on many materials

Engrave Modes

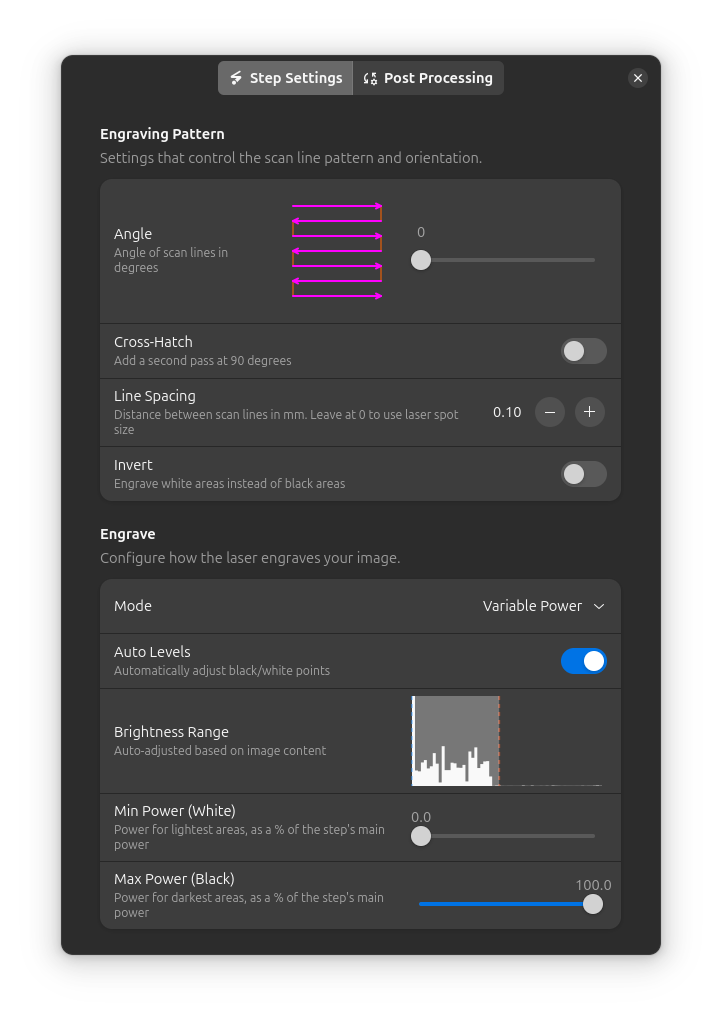

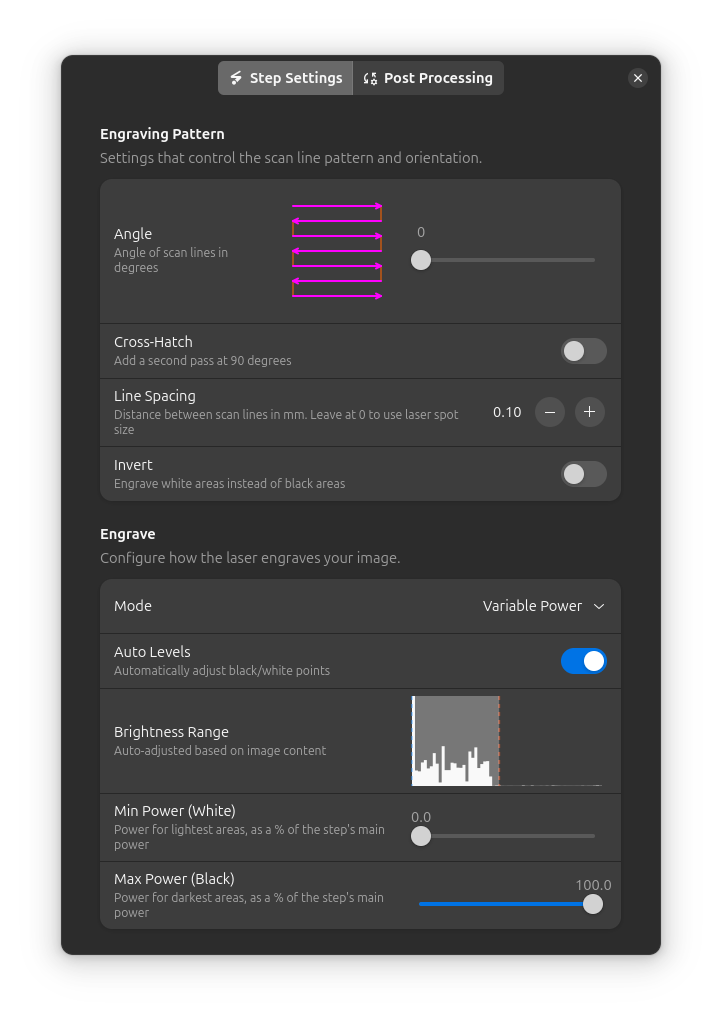

Variable Power Mode

Variable Power mode varies laser power continuously based on image brightness, creating smooth grayscale engraving with gradual transitions.

Best For:

- Smooth grayscale photos and images

- Natural gradients and transitions

- Portraits and artwork

- Wood and leather engraving

Key Features:

- Continuous power modulation

- Min/max power control

- Smooth gradients

- Better tonal quality than dithering

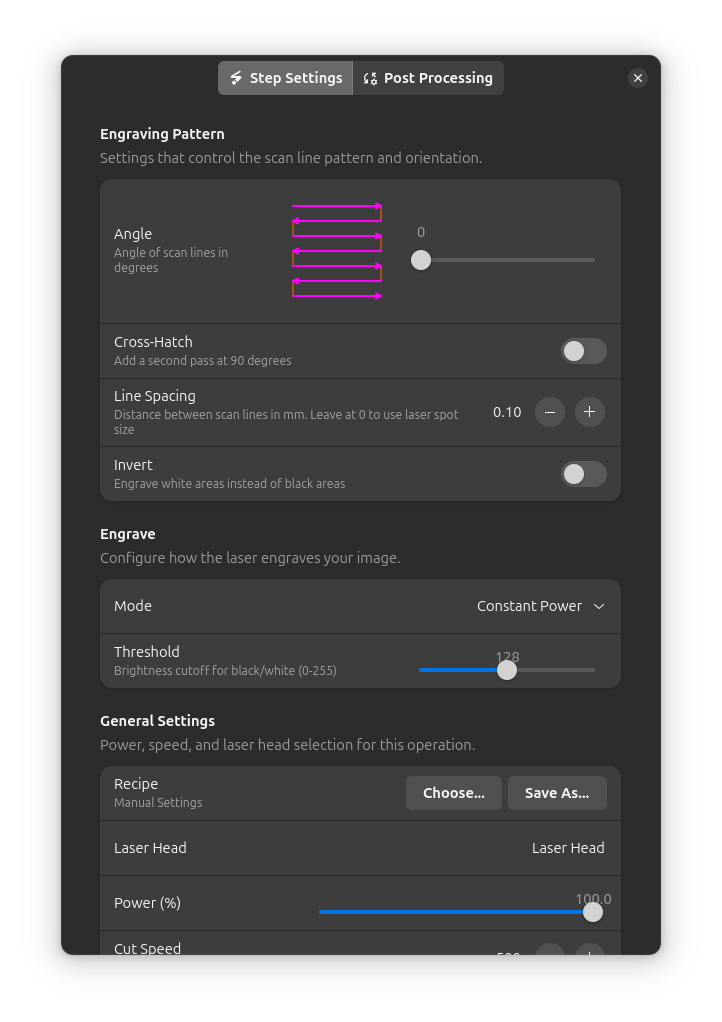

Constant Power Mode

Constant Power mode engraves at full power, with a threshold determining which pixels are engraved. This creates clean black/white results.

Best For:

- Text and logos

- High-contrast graphics

- Clean black/white engravings

- Simple shapes and patterns

Key Features:

- Threshold-based engraving

- Consistent power output

- Faster than variable power mode

- Clean edges

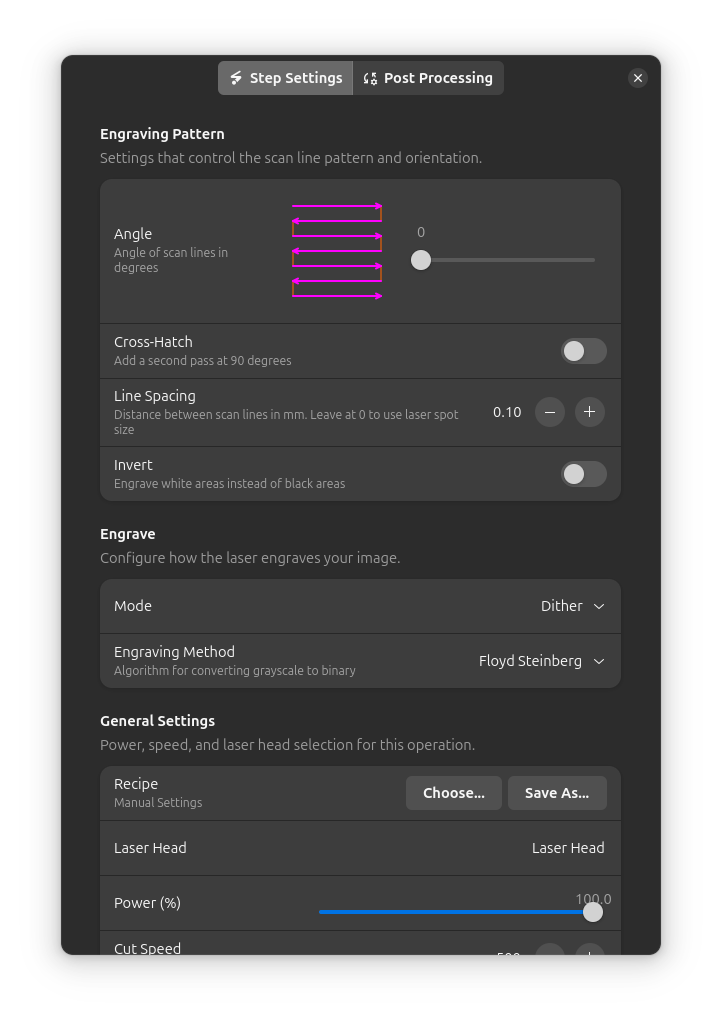

Dither Mode

Dither mode converts grayscale images to binary patterns using dithering algorithms, enabling high-quality photo engraving with better tonal reproduction than simple threshold-based methods.

Best For:

- Engraving photographs on wood or leather

- Creating halftone-style artwork

- Images with smooth gradients

- When standard raster doesn't capture enough detail

Key Features:

- Multiple dithering algorithm choices

- Better detail preservation

- Perceived continuous tones

- Ideal for photographs

Multiple Depths Mode

Multiple Depths mode creates 3D relief effects by varying laser power based on image brightness, with multiple passes for deeper carving.

Best For:

- Creating 3D portraits and artwork

- Terrain and topographic maps

- Lithophanes (light-transmitting 3D images)

- Embossed logos and designs

- Relief sculptures

Key Features:

- Depth mapping from image brightness

- Configurable min/max depth

- Smooth gradients

- Multiple passes for deeper engraving

- Z-stepping between passes

When to Use Engrave

Use engrave operations for:

- Engraving text and logos

- Creating images and photos on wood/leather

- Filling solid areas with texture

- Marking parts and products

- Creating 3D relief effects

- Halftone-style artwork

Don't use engrave for:

- Cutting through material (use Contour instead)

- Precise outlines (raster creates filled areas)

- Fine line work (vectors are cleaner)

Creating an Engrave Operation

Step 1: Prepare Content

Engrave works with:

- Vector shapes - Filled with scanning lines

- Text - Converted to filled paths

- Images - Converted to grayscale and engraved

Step 2: Add Engrave Operation

- Menu: Operations → Add Engrave

- Shortcut: ctrl+shift+e

- Right-click: Context menu → Add Operation → Engrave

Step 3: Choose Mode

Select the engraving mode that best suits your needs:

- Variable Power - Smooth grayscale engraving

- Constant Power - Clean black/white engraving

- Dither - High-quality photo engraving

- Multiple Depths - 3D relief effects

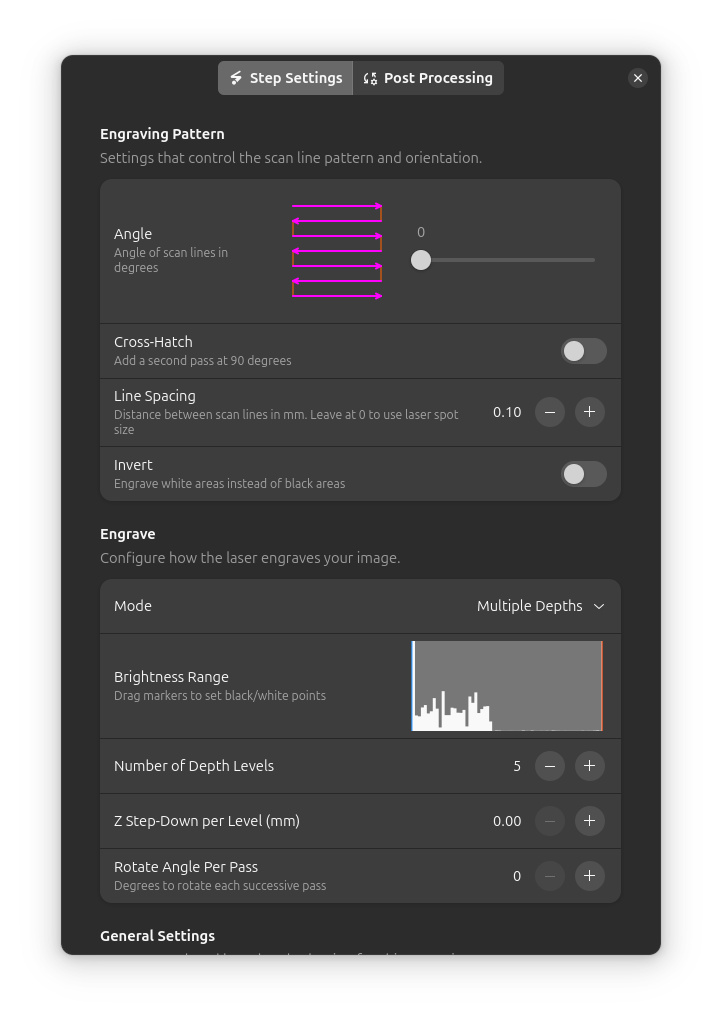

Step 4: Configure Settings

Common Settings

Power & Speed

Power (%):

- Laser intensity for engraving

- Lower power for lighter marking

- Higher power for deeper engraving

Speed (mm/min):

- How fast the laser scans

- Faster = lighter, slower = darker

Line Interval

Line Interval (mm):

- Spacing between scan lines

- Smaller = higher quality, longer job time

- Larger = faster, visible lines

| Interval | Quality | Speed | Use For |

|---|---|---|---|

| 0.05mm | Highest | Slowest | Photos, fine detail |

| 0.1mm | High | Medium | Text, logos, graphics |

| 0.2mm | Medium | Fast | Solid fills, textures |

| 0.3mm+ | Low | Fastest | Draft, testing |

Recommended: 0.1mm for general use

For images, line interval should match or exceed image resolution. If your image is 10 pixels/mm (254 DPI), use 0.1mm line interval or smaller.

Scan Direction

Scan Angle (degrees):

- Direction of scan lines

- 0 = horizontal (left to right)

- 90 = vertical (top to bottom)

- 45 = diagonal

Why change angle?

- Wood grain: Engrave perpendicular to grain for better results

- Pattern orientation: Match design aesthetics

- Reduce banding: Different angle can hide imperfections

Bidirectional Scanning:

- Enabled: Laser engraves in both directions (faster)

- Disabled: Laser only engraves left-to-right (slower, more consistent)

For best quality, disable bidirectional. For speed, enable it.

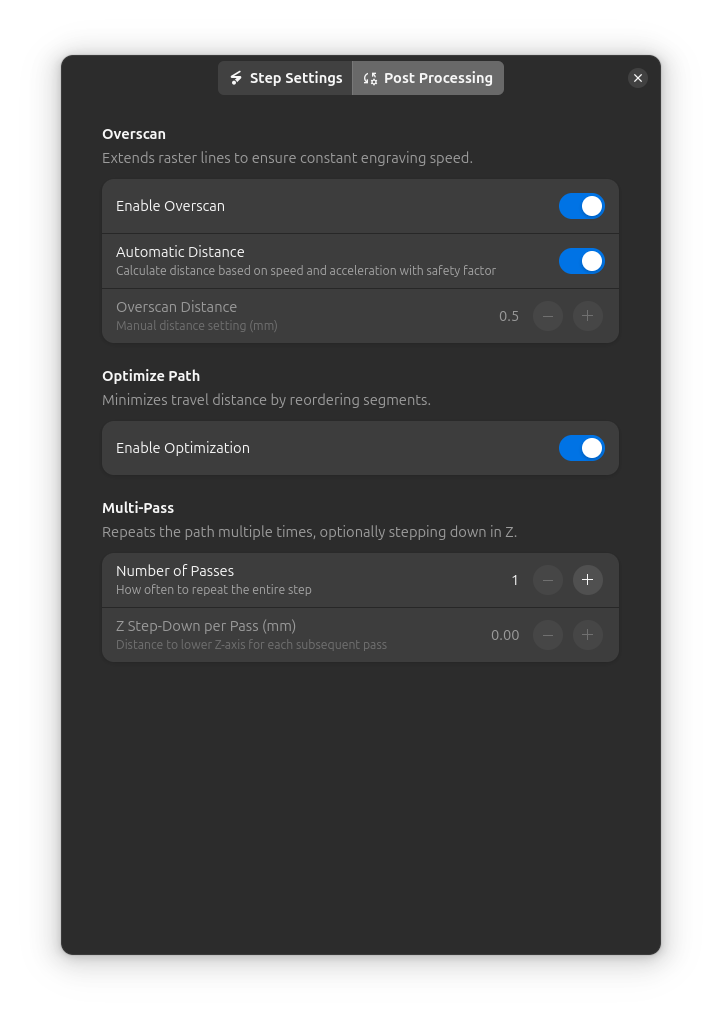

Overscan

Overscan Distance (mm):

- How far beyond the design the laser travels before turning around

- Allows laser to reach full speed before entering the design

- Prevents burn marks at line starts/ends

Typical values:

- 2-5mm for most jobs

- Larger for high speeds

See Overscan for details.

Mode-Specific Settings

Variable Power Mode Settings

Min Power (%):

- Laser power for lightest areas (white pixels)

- Usually 0-20%

- Set higher to avoid very shallow areas

Max Power (%):

- Laser power for darkest areas (black pixels)

- Usually 40-80% depending on material

- Lower = subtle relief, higher = dramatic depth

Power Range Examples:

| Min | Max | Effect |

|---|---|---|

| 0% | 40% | Subtle, light relief |

| 10% | 60% | Medium depth, safe |

| 20% | 80% | Deep, dramatic relief |

Invert:

- Off (default): White = shallow, Black = deep

- On: White = deep, Black = shallow

Use invert for lithophanes (light areas should be thin) or embossing (raised areas).

Brightness Range:

Controls how image brightness values are mapped to laser power. The histogram shows the distribution of brightness values in your image.

- Auto Levels (default): Automatically adjusts the black and white points based on image content. Values below the black point are treated as black, values above the white point are treated as white. This stretches the image's contrast to use the full power range.

- Manual Mode: Disable Auto Levels to manually set black and white points by dragging the markers on the histogram.

This is particularly useful for:

- Low-contrast images that need contrast enhancement

- Images with limited tonal range

- Ensuring consistent results across different source images

Constant Power Mode Settings

Threshold (0-255):

- Brightness cutoff for black/white separation

- Lower = more black engraved

- Higher = more white engraved

Typical values:

- 128 (50% gray threshold)

- Adjust based on image contrast

Dither Mode Settings

Dithering Algorithm:

Choose the algorithm that best suits your image and material:

| Algorithm | Quality | Speed | Best For |

|---|---|---|---|

| Floyd-Steinberg | Highest | Slowest | Photos, portraits, smooth gradients |

| Bayer 2x2 | Low | Fastest | Coarse halftone effect |

| Bayer 4x4 | Medium | Fast | Balanced halftone |

| Bayer 8x8 | High | Medium | Fine detail, subtle patterns |

Floyd-Steinberg is default and recommended for most photo engravings. It uses error diffusion to distribute quantization errors to neighboring pixels, creating natural-looking results.

Bayer dithering creates regular patterns that can produce artistic effects resembling traditional halftone printing.

Multiple Depths Mode Settings

Number of Depth Levels:

- Number of discrete depth levels

- More levels = smoother gradients

- Typical: 5-10 levels

Z Step-Down per Level (mm):

- How far to step down between depth passes

- Creates deeper total depth with multiple passes

- Typical: 0.1-0.5mm

Rotate Angle Per Pass:

- Degrees to rotate each successive pass

- Creates crosshatch-like 3D effect

- Typical: 0-45 degrees

Invert:

- Enabled: White = deep, Black = shallow

- Disabled: Black = deep, White = shallow

Use invert for lithophanes (light areas should be thin) or embossing (raised areas).

Tips & Best Practices

Material Selection

Best materials for engraving:

- Wood (natural variations create beautiful results)

- Leather (burns to dark brown/black)

- Anodized aluminum (removes coating, reveals metal)

- Coated metals (removes coating layer)

- Some plastics (test first!)

Challenging materials:

- Clear acrylic (doesn't show engraving well)

- Metals without coating (requires special marking compounds)

- Glass (requires special settings/coatings)

Quality Settings

For best quality:

- Use smaller line interval (0.05-0.1mm)

- Disable bidirectional scanning

- Increase overscan (3-5mm)

- Use lower power, multiple passes

- Ensure material is flat and secured

For faster engraving:

- Use larger line interval (0.15-0.2mm)

- Enable bidirectional scanning

- Minimum overscan (1-2mm)

- Single pass at higher power

Common Issues

Burn marks at line ends:

- Increase overscan distance

- Check acceleration settings

- Reduce power slightly

Visible scan lines:

- Decrease line interval

- Reduce power (over-burning creates gaps)

- Check that material is flat

Uneven engraving:

- Ensure material is flat

- Check focus consistency

- Verify laser power stability

- Clean laser lens

Banding (dark/light stripes):

- Disable bidirectional scanning

- Check belt tension

- Reduce speed

- Try different scan angle

Troubleshooting

Engraving too light

- Increase: Power setting

- Decrease: Speed setting

- Check: Focus is correct

- Try: Multiple passes

Engraving too dark/burning

- Decrease: Power setting

- Increase: Speed setting

- Increase: Line interval

- Check: Material is appropriate

Inconsistent darkness

- Check: Material is flat

- Check: Focus distance is consistent

- Verify: Laser beam is clean

- Test: Different area of material (grain varies)

Image looks pixelated

- Decrease: Line interval

- Check: Source image resolution

- Try: Smaller line interval (0.05mm)

- Verify: Image isn't being upscaled

Scan lines visible

- Decrease: Line interval

- Reduce: Power (over-burning creates gaps)

- Try: Different scan angle

- Ensure: Material surface is smooth

Related Topics

- Contour Cutting - Cutting outlines and shapes

- Overscan - Improving engraving quality

- Material Test Grid - Finding optimal settings

- Multi-Layer Workflow - Combining engrave with other operations