Material Test Grid

The Material Test Grid generator creates parametric test patterns to help you find optimal laser settings for different materials.

Overview

Material testing is essential for laser work - different materials require different power and speed settings. The Material Test Grid automates this process by:

- Generating test grids with configurable speed/power ranges

- Providing presets for common laser types (Diode, CO2)

- Optimizing execution order for safety (fastest speeds first)

- Adding labels to identify each test cell's settings

Creating a Material Test Grid

Step 1: Open the Generator

Access the Material Test Grid generator:

- Menu: Tools → Material Test Grid

- This creates a special workpiece that generates the test pattern

Step 2: Choose a Preset (Optional)

Rayforge includes presets for common scenarios:

| Preset | Speed Range | Power Range | Use For |

|---|---|---|---|

| Diode Engrave | 1000-10000 mm/min | 10-100% | Diode laser engraving |

| Diode Cut | 100-5000 mm/min | 50-100% | Diode laser cutting |

| CO2 Engrave | 3000-20000 mm/min | 10-50% | CO2 laser engraving |

| CO2 Cut | 1000-20000 mm/min | 30-100% | CO2 laser cutting |

Presets are starting points - you can adjust all parameters after selecting one.

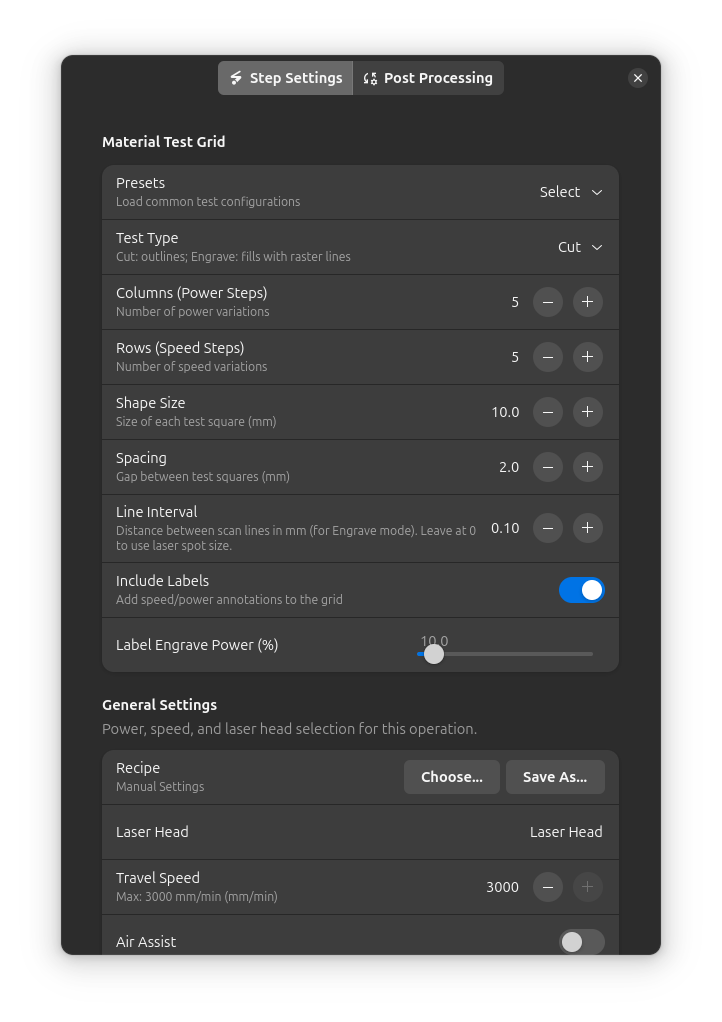

Step 3: Configure Parameters

Adjust the test grid parameters in the settings dialog:

Test Type

- Engrave: Fills squares with raster pattern

- Cut: Cuts outline of squares

Speed Range

- Min Speed: Slowest speed to test (mm/min)

- Max Speed: Fastest speed to test (mm/min)

- Columns in grid represent different speeds

Power Range

- Min Power: Lowest power to test (%)

- Max Power: Highest power to test (%)

- Rows in grid represent different power levels

Grid Dimensions

- Columns: Number of speed variations (typically 3-7)

- Rows: Number of power variations (typically 3-7)

Size & Spacing

- Shape Size: Size of each test square in mm (default: 20mm)

- Spacing: Gap between squares in mm (default: 5mm)

Labels

- Include Labels: Enable/disable axis labels showing speed and power values

- Labels appear on left and top edges

- Labels are engraved at 10% power, 1000 mm/min

Step 4: Generate the Grid

Click Generate to create the test pattern. The grid appears on your canvas as a special workpiece.

Understanding the Grid Layout

Grid Organization

Power (%) Speed (mm/min) →

↓ 1000 2500 5000 7500 10000

100% [ ] [ ] [ ] [ ] [ ]

75% [ ] [ ] [ ] [ ] [ ]

50% [ ] [ ] [ ] [ ] [ ]

25% [ ] [ ] [ ] [ ] [ ]

10% [ ] [ ] [ ] [ ] [ ]

- Columns: Speed increases from left to right

- Rows: Power increases from bottom to top

- Labels: Show exact values for each row/column

Grid Size Calculation

Without labels:

- Width = columns × (shape_size + spacing) - spacing

- Height = rows × (shape_size + spacing) - spacing

With labels:

- Add 15mm margin to left and top for label space

Example: 5×5 grid with 20mm squares and 5mm spacing:

- Without labels: 120mm × 120mm

- With labels: 135mm × 135mm

Execution Order (Risk Optimization)

Rayforge executes test cells in a risk-optimized order to prevent material damage:

- Highest speed first: Fast speeds are safer (less heat buildup)

- Lowest power within speed: Minimizes risk at each speed level

This prevents charring or fire from starting with slow, high-power combinations.

Example execution order for 3×3 grid:

Order: 1 2 3

4 5 6 ← Highest speed, power increasing

7 8 9

(Fastest speed/lowest power executed first)

Using Material Test Results

Step 1: Run the Test

- Load your material in the laser

- Focus the laser properly

- Run the material test grid job

- Monitor the test - stop if any cell causes problems

Step 2: Evaluate Results

After the test completes, examine each cell:

- Too light: Increase power or decrease speed

- Too dark/charred: Decrease power or increase speed

- Perfect: Note the speed/power combination

Step 3: Record Settings

Document your successful settings for future reference:

- Material type and thickness

- Operation type (engrave or cut)

- Speed and power combination

- Number of passes

- Any special notes

Consider creating a reference document with your material test results for quick lookup in future projects.

Advanced Usage

Combining with Other Operations

Material test grids are regular workpieces - you can combine them with other operations:

Example workflow:

- Create material test grid

- Add contour cut around the entire grid

- Run test, cut free, evaluate results

This is useful for cutting the test piece free from stock material.

Custom Test Ranges

For fine-tuning, create narrow-range tests:

Coarse test (find ballpark):

- Speed: 1000-10000 mm/min (5 columns)

- Power: 10-100% (5 rows)

Fine test (optimize):

- Speed: 4000-6000 mm/min (5 columns)

- Power: 35-45% (5 rows)

Different Materials, Same Grid

Run the same grid configuration on different materials to build your material library faster.

Tips & Best Practices

Grid Design

✅ Start with presets - Good starting points for common scenarios ✅ Use 5×5 grids - Good balance of detail and test time ✅ Enable labels - Essential for identifying results ✅ Keep squares ≥20mm - Easier to see and measure results

Testing Strategy

✅ Test scrap first - Never test on final material ✅ One variable at a time - Test speed OR power range, not both extremes ✅ Allow cooldown - Wait between tests on same material ✅ Consistent focus - Same focus distance for all tests

Safety

⚠️ Monitor tests - Never leave running tests unattended ⚠️ Start conservative - Begin with lower power ranges ⚠️ Check ventilation - Ensure proper fume extraction ⚠️ Fire watch - Have fire extinguisher ready

Troubleshooting

Test cells execute in wrong order

- Rayforge uses risk-optimized order (fastest speeds first)

- This is intentional and cannot be changed

- See Execution Order above

Results are inconsistent

- Check: Material is flat and properly secured

- Check: Focus is consistent across entire test area

- Check: Laser power is stable (check power supply)

- Try: Smaller grid to reduce test area

Related Topics

- Simulation Mode - Preview test execution before running

- Engrave - Understanding engrave operations

- Contour Cutting - Understanding cut operations